Petestop® Inflatable Line Stop Insertion Systems

128 Series, PeteStop® Line Stop Insertion System

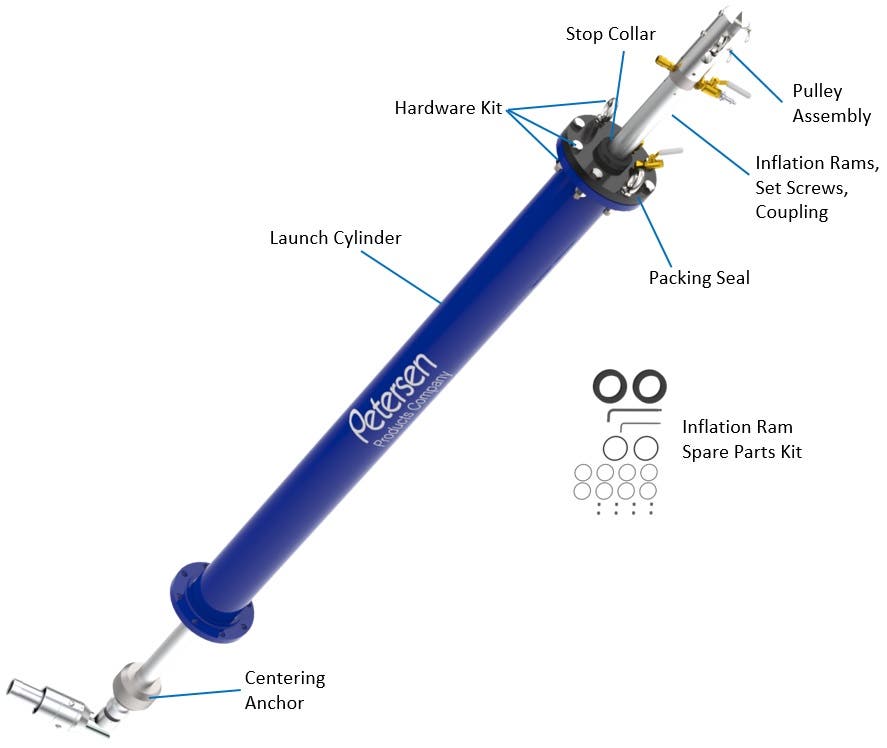

PeteStop® 128-Series Insertion System Kits

The 128-Series Plug has the smallest tap hole of the PeteStop® inflatable plugs.

128-Series Insertion System Kits consist of:

- Launch Cylinder(s)

- Inflation Ram(s), Set Screws, Coupling (if needed)

- Inflation Pulley Assembly

- Packing Seal

- Centering Anchor

- Hardware Kit - Bolts, Eyebolts, Nuts, Gasket

- Inflation Ram Spare Parts Kit

Does not include 128-Series Plug & Rotating Elbow

| Image | Dia., Inflated Plug | Hot Tap Hole Size | Dia., Inflation Ram | Infl. Ram Pkg. Seal ID/OD | Lngth, Launch Cyl. | Dia., Launch Cyl. | Connection Type | Shipping Wt. | Item Number | Price | Qty | Action |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

72" (1829mm) | 15" (381mm) | 2.5" (64mm) | 2.5" (64mm) / 16" (406mm) 150 Lb Flange | 288" (7315mm) | 16" (406mm) | 16" (406mm) x 150 Lb Flange | 2100 Lb (950 Kg) | 938-072-KIT |

$21,203.10

|

|

|

|

66" (1676mm) | 13" (330mm) | 2.5" (64mm) | 2.5" (64mm) / 14" (356mm) 150 Lb Flange | 264" (6706mm) | 14" (356mm) | 14" (356mm) x 150 Lb Flange | 1900 Lb (860 Kg) | 938-066-KIT |

$16,323.02

|

|

|

|

60" (1524mm) | 13" (330mm) | 2.5" (64mm) | 2.5" (64mm) / 14" (356mm) 150 Lb Flange | 252" (6401mm) | 14" (356mm) | 14" (356mm) x 150 Lb Flange | 1700 Lb (770 Kg) | 938-060-KIT |

$15,881.80

|

|

|

|

54" (1372mm) | 11.75" (298mm) | 2.5" (64mm) | 2.5" (64mm) / 12" (305mm) 150 Lb Flange | 228" (5791mm) | 12" (305mm) | 12" (305mm) x 150 Lb Flange | 1500 Lb (680 Kg) | 938-054-KIT |

$12,304.73

|

|

|

|

48" (1219mm) | 9.75" (248mm) | 2.5" (64mm) | 2.5" (64mm) / 10" (254mm) 150 Lb Flange | 192" (4877mm) | 10" (254mm) | 10" (254mm) x 150 Lb Flange | 1317 Lb (597 Kg) | 938-048-KIT |

$10,837.30

|

|

|

|

42" (1067mm) | 9.75" (248mm) | 2.5" (64mm) | 2.5" (64mm) / 10" (254mm) 150 Lb Flange | 180" (4572mm) | 10" (254mm) | 10" (254mm) x 150 Lb Flange | 1241 Lb (563 Kg) | 938-042-KIT |

$9,511.95

|

|

|

|

36" (914mm) | 9.75" (248mm) | 2.5" (64mm) | 2.5" (64mm) / 10" (254mm) 150 Lb Flange | 156" (3962mm) | 10" (254mm) | 10" (254mm) x 150 Lb Flange | 1043 Lb (473 Kg) | 938-036-KIT |

$8,464.67

|

|

|

|

32"-33" (813mm-838mm) | 9.75" (248mm) | 2.5" (64mm) | 2.5" (64mm) / 10" (254mm) 150 Lb Flange | 144" (3658mm) | 10" (254mm) | 10" (254mm) x 150 Lb Flange | 1003 Lb (455 Kg) | 938-032-KIT |

$7,764.39

|

|

|

|

30" (762mm) | 7.875" (200mm) | 2.5" (64mm) | 2.5" (64mm) / 8" (203mm) 150 Lb Flange | 132" (3353mm) | 8" (203mm) | 8" (203mm) x 150 Lb Flange | 836 Lb (379 Kg) | 938-030-KIT |

$6,717.85

|

|

|

|

24" (610mm) | 7.75" (197mm) | 2.5" (64mm) | 2.5" (64mm) / 8" (203mm) 150 Lb Flange | 108" (2743mm) | 8" (203mm) | 8" (203mm) x 150 Lb Flange | 732 Lb (332 Kg) | 938-024-KIT |

$6,067.38

|

|

|

|

20" (508mm) | 7.75" (197mm) | 2.5" (64mm) | 2.5" (64mm) / 8" (203mm) 150 Lb Flange | 96" (2438mm) | 8" (203mm) | 8" (203mm) x 150 Lb Flange | 652 Lb (296 Kg) | 938-020-KIT |

$5,618.77

|

|

|

|

18" (457mm) | 7.75" (197mm) | 2.5" (64mm) | 2.5" (64mm) / 8" (203mm) 150 Lb Flange | 84" (2134mm) | 8" (203mm) | 8" (203mm) x 150 Lb Flange | 535 Lb (243 Kg) | 938-018-KIT |

$4,747.28

|

|

|

|

16" (406mm) | 5.75" (146mm) | 2.5" (64mm) | 2.5" (64mm) / 6" (152mm) 150 Lb Flange | 84" (2134mm) | 6" (152mm) | 6" (152mm) x 150 Lb Flange | 376 Lb (171 Kg) | 938-016-KIT |

$4,499.00

|

|

|

|

12"-15" (305mm-381mm) | 5.75" (146mm) | 2.5" (64mm) | 2.5" (64mm) / 6" (152mm) 150 Lb Flange | 72" (1829mm) | 6" (152mm) | 6" (152mm) x 150 Lb Flange | 347 Lb (157 Kg) | 938-012-KIT |

$4,380.09

|

|

|

|

10" (254mm) | 5.75" (146mm) | 1.875" (48mm) | 1.875" (48mm) / 6" (152mm) 150 Lb Flange | 60" (1524mm) | 6" (152mm) | 6" (152mm) x 150 Lb Flange | 278 Lb (126 Kg) | 938-010-KIT |

$3,573.08

|

|

|

|

8" (203mm) | 5.75" (146mm) | 1.875" (48mm) | 1.875" (48mm) / 6" (152mm) 150 Lb Flange | 48" (1219mm) | 6" (152mm) | 6" (152mm) x 150 Lb Flange | 253 Lb (115 Kg) | 938-008-KIT |

$3,423.85

|

|

|

|

5"-6" (127mm-152mm) | 3.75" (95mm) | 1" (25mm) | 1" (25mm) x 4" (102mm) 150 Lb Flange | 36" (914mm) | 4" (102mm) | 4" (102mm) x 150 Lb Flange | 116 Lb (52.6 Kg) | 938-006-KIT |

$2,346.92

|

|

|

|

4" (102mm) | 2.875" (73mm) | 1" (25mm) | 1" (25mm) X 3" (76mm) NPT | 36" (914mm) | 3" (76mm) | 3" MNPT (76mm) | 51 Lb (23.1 Kg) | 938-004-KIT |

$1,752.00

|

|

|

|

2"-3" (51mm-76mm) | 1.875" (48mm) | 1" (25mm) | 1" (25mm) X 2" (51mm) NPT | 24" (610mm) | 2" (51mm) | 2" MNPT (51mm) | 27 Lb (12.3 Kg) | 938-002-KIT |

$1,680.00

|

|

129 Series, PeteStop® Line Stop Insertion System

PeteStop® 129-Series Insertion System Kits

The 129-Series Plug is the best selling of the PeteStop® inflatable plugs.

The 129-Series Insertion System Kits consist of:

- Launch Cylinder(s)

- Inflation Ram(s), Set Screws, Coupling (if needed)

- Inflation Pulley Assembly

- Packing Seal

- Centering Anchor

- Hardware Kit - Bolts, Eyebolts, Nuts, Gasket

- Inflation Ram Spare Parts Kit

Does not include 129-Series PeteStop® Plug, Retraction System & Inflation Kit.

| Image | Dia., Inflated Plug | Dia., Inflation Ram | Infl. Ram Pkg. Seal ID/OD | Dia., Launch Cyl. | Connection Type | Shipping Wt. | Item Number | Price | Qty | Action |

|---|---|---|---|---|---|---|---|---|---|---|

|

84" (2134mm) | 2.5" (64mm) | 20" (508mm) x 150 Lb Flange | 20" (508mm) | 20" (508mm) x 150 Lb Flange | 3000 Lb (1360.79 Kg) | 939-084-KITWATER |

$18,131.46

|

|

|

|

72" (1829mm) | 2.5" (64mm) | 2.5 OD Ram/20" (508mm) x 150 Lb Flange | 20" (508mm) | 20" (508mm) x 150 Lb Flange | 2895 Lb (1313.16 Kg) | 939-072-KITWATER |

$17,673.46

|

|

|

|

66" (1676mm) | 2.5" (64mm) | 18" (457mm) x 150 Lb Flange | 18" (457mm) | 18" (457mm) x 150 Lb Flange | 2052 Lb (930.78 Kg) | 939-066-KITWATER |

$14,760.06

|

|

|

|

60" (1524mm) | 2.5" (64mm) | 18" (457mm) x 150 Lb Flange | 18" (457mm) | 18" (457mm) x 150 Lb Flange | 1747 Lb (792 Kg) | 939-060-KITWATER |

$13,711.24

|

|

|

|

54" (1372mm) | 2.5" (64mm) | 16" (406mm) x 150 Lb Flange | 16" (406mm) | 16" (406mm) x 150 Lb Flange | 1468 Lb (665.88 Kg) | 939-054-KIT |

$8,646.30

|

|

|

|

48" (1219mm) | 2.5" (64mm) | 16" (406mm) x 150 Lb Flange | 16" (406.4mm) | 16" (406mm) x 150 Lb Flange | 1387 Lb (629.14 Kg) | 939-048-KIT |

$7,582.30

|

|

|

|

42" (1067mm) | 2.5" (64mm) | 16" (406mm) x 150 Lb Flange | 16" (406mm) | 16" (406mm) x 150 Lb Flange | 1314 Lb (596.03 Kg) | 939-042-KIT |

$7,286.90

|

|

|

|

36" (914mm) | 2.5" (64mm) | 12" (305mm) x 150 Lb Flange | 12" (305mm) | 12" (305mm) x 150 Lb Flange | 748 Lb (339.29 Kg) | 939-036-KIT |

$5,559.70

|

|

|

|

30"-33" (762mm-838mm) | 2.5" (64mm) | 12" (305mm) x 150 Lb Flange | 12" (305mm) | 12" (305mm) x 150 Lb Flange | 685 Lb (310.71 Kg) | 939-02833-KIT |

$4,890.50

|

|

|

|

24" (610mm) | 2.5" (64mm) | 12" (305mm) x 150 Lb Flange | 12" (305mm) | 12" (305mm) x 150 Lb Flange | 635 Lb (288.03 Kg) | 939-024-KIT |

$4,728.30

|

|

|

|

16"-20" (406mm-508mm) | 1.875" (48mm) | 10" (254mm) x 150 Lb Flange | 10" (254mm) | 10" (254mm) x 150 Lb Flange | 396 Lb (179.62 Kg) | 939-01620-KIT |

$4,029.20

|

|

|

|

12"-15" (305-381mm) | 1.875" (48mm) | 8" 150 Lb Flange | 8" (203mm) | 8" (203mm) x 150 Lb Flange | 289 Lb (131.09 Kg) | 939-01215-KIT |

$3,482.20

|

|

|

|

8"-10" (203-254mm) | 1" (25mm) | 1" (25mm) / 6" (152mm) 150 Lb Flange | 6" (152mm) | 6" (152mm) x 150 Lb Flange | 127 Lb (57.61 Kg) | 939-00810-KIT |

$2,626.00

|

|

|

|

5"-6" (127mm-152mm) | 1" (25mm) | 1" (25mm) x 4" (102mm) 150 Lb Flange | 4" (102mm) | 4" (102mm) x 150 Lb Flange | 84 Lb (38.10 Kg) | 939-006-KIT |

$2,234.80

|

|

|

|

4" (102mm) | 1" (25mm) | 1" (25mm) x 4" (102mm) 150 Lb Flange | 4" (102mm) | 4" (102mm) x 150 Lb Flange | 75 Lb (34.02 Kg) | 939-004-KIT1 |

$2,027.75

|

|

|

|

3" (76mm) | 1" (25mm) | 1" (25mm) X 3" (76mm) NPT | 3" (76mm) | 3" MNPT (76mm) | 23 Lb (10.43 Kg) | 939-003-KIT |

$1,558.00

|

|

|

|

2" (51mm) | 1" (25mm) | 1" (25mm) X 2" (51mm) NPT | 2" (51mm) | 2" MNPT (51mm) | 20 Lb (9.07 Kg) | 939-002-KIT |

$1,443.00

|

|

129HP Series, PeteStop® Line Stop Insertion System

| Image | Item Number | Price | Qty | Action |

|---|---|---|---|---|

|

939-096-KITWATER |

$25,403.61

|

|

|

|

939-096-KITHP |

$62,271.00

|

|

|

|

939-084-KITHP |

$46,858.00

|

|

|

|

939-072-KITHP |

$37,757.00

|

|

|

|

939-066-KITHP |

$34,254.00

|

|

|

|

939-060-KITHP |

$25,597.80

|

|

|

|

939-054-KITHP |

$22,628.30

|

|

|

|

939-048-KITHP |

$13,274.40

|

|

|

|

939-042-KITHP |

$11,821.29

|

|

|

|

939-036-KITHP |

$11,821.29

|

|

|

|

939-032-KIT |

$11,403.18

|

|

|

|

939-02830-KIT |

$8,249.85

|

|

|

|

939-024-KITHP |

$7,257.50

|

|

|

|

939-020-KIT |

$6,298.10

|

|

|

|

939-018-KIT |

$6,298.10

|

|

|

|

939-016-KIT |

$6,260.10

|

|

|

|

939-014-KIT |

$5,418.20

|

|

|

|

939-012-KIT |

$5,085.20

|

|

|

|

939-010-KIT |

$4,448.20

|

|

|

|

939-008-KITHP |

$2,820.60

|

|

|

|

939-004-KIT |

$1,678.00

|

|