For 1/4” to 6" Diameter Taps in pneumatic pipelines

The Petersen® 262-2040 Pneumatic Hot Tapper is sized for limited space and light weight one man operation. It will tap larger holes than any manual crank Tapper and air pressure will allow it to tap up to 6” diameter holes often at least as fast as larger hydraulic machines.

- Taps ¼” to 5 ¾” diameter holes

- Low cost, much less than hydraulic tappers

- Far more efficient and larger holes than the hand crank tappers

- Light weight for one-man operation

- Pneumatic cutter force adjustable for each size and pipe material

- Works with any electric, hydraulic, or pneumatic drill motor with a standard ½” chuck

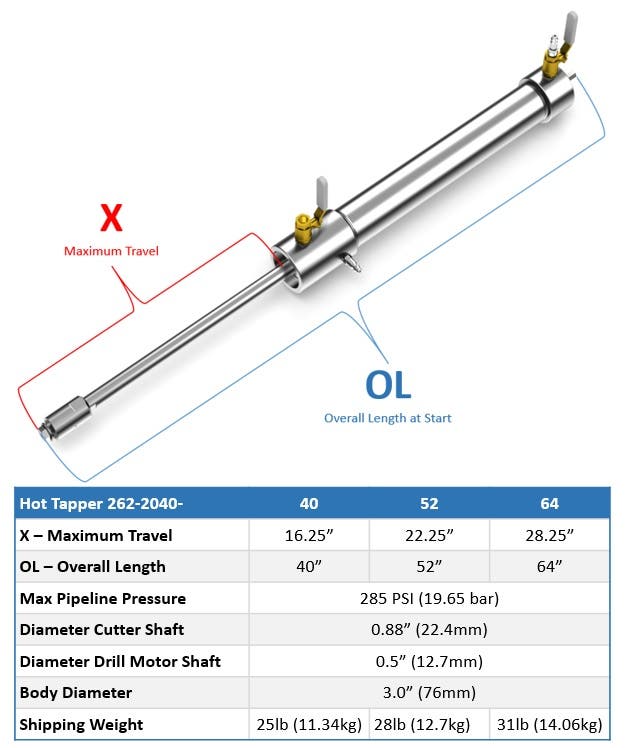

| Image | Press. Pipeline Max | Description | Shipping Wt. | Item Number | Price | Qty | Order or Compare |

|---|---|---|---|---|---|---|---|

|

285 psi (19.65 bar) | Pneumatic Hot Tapping Machine, 1/4" to 6" Capacity, 64" Overall Length | 31 Lb (14.06 Kg) | 262-2040-64 |

$3,360.00

|

||

|

285 psi (19.65 bar) | Pneumatic Hot Tapping Machine, 1/4" to 6" Capacity, 52" Overall Length | 28 Lb (12.70 Kg) | 262-2040-52 |

$3,050.00

|

||

|

285 psi (19.65 bar) | Pneumatic Hot Tapping Machine, 1/4" to 6" Capacity, 40" Overall Length | 25 Lb (11.34 Kg) | 262-2040-40 |

$2,780.00

|

| Image | Description | Tapper Valve Adapter | Length | Shipping Wt. | Item Number | Price | Qty | Order or Compare |

|---|---|---|---|---|---|---|---|---|

|

Flange Adapter 6" X 300# | 6" (152.4mm) | 5.6" (142.24mm) | 55 Lb (24.95 Kg) | 262-2040-3060 |

$1,560.00

|

||

|

Flange Adapter 4" X 300# | 4" (101.6mm) | 5.1" (129.54mm) | 29 Lb (13.15 Kg) | 262-2040-3040 |

$1,400.00

|

||

|

Flange Adapter 3" X 300# | 3" (76.2mm) | 4.8" (121.92mm) | 19 Lb (8.62 Kg) | 262-2040-3030 |

$1,240.00

|

||

|

Flange Adapter 6" X 150# | 6" (152.4mm) | 5.2" (132.08mm) | 26 Lb (11.79 Kg) | 262-2040-1060 |

$1,120.00

|

||

|

Flange Adapter 4" X 150# | 4" (101.6mm) | 4.7" (119.38mm) | 18 Lb (8.16 Kg) | 262-2040-1040 |

$872.00

|

||

|

Flange Adapter 3" X 150# | 3" (76.2mm) | 4.4" (111.76mm) | 13 Lb (5.90 Kg) | 262-2040-1030 |

$801.00

|

||

|

Adapter 6" NPT | 6" (152.4mm) | 7.5" (190.5mm) | 11 Lb (4.99 Kg) | 262-2040-0060 |

$819.00

|

||

|

Adapter 5" NPT | 5" (127mm) | 7.2" (182.88mm) | 8 Lb (3.63 Kg) | 262-2040-0050 |

$662.00

|

||

|

Adapter 4" NPT | 4" (101.6mm) | 7.2" (182.88mm) | 7 Lb (3.18 Kg) | 262-2040-0040 |

$266.00

|

||

|

Adapter 3" NPT | 3" (76.2mm) | 7" (177.8mm) | 5 Lb (2.27 Kg) | 262-2040-0030 |

$125.00

|

||

|

Adapter 2-1/2" NPT | 2-1/2" (63.5mm) | 6.7" (170.18mm) | 4 Lb (1.81 Kg) | 262-2040-0025 |

$103.00

|

||

|

Adapter 2" NPT | 2" (50.8mm) | 4" (101.6mm) | 1 Lb (0.45 Kg) | 262-2040-0020 |

$28.40

|

||

|

Adapter 1-1/2" NPT | 1-1/2" (38.1mm) | 5.4" (137.16mm) | 2 Lb (0.91 Kg) | 262-2040-0015 |

$124.00

|

||

|

Adapter 1-1/4" NPT | 1-1/4" (31.75mm) | 5.4" (137.16mm) | 2 Lb (0.91 Kg) | 262-2040-0012 |

$54.40

|

||

|

Adapter, 1" NPT | 1" (25.4mm) | 5.4" (137.16mm) | 2 Lb (0.91 Kg) | 262-2040-0010 |

$35.50

|

| Image | Description | Shipping Wt. | Item Number | Price | Qty | Order or Compare |

|---|---|---|---|---|---|---|

|

Tap Drill, Arbor, 1.375" (34.92mm) - 6.0" (152.4mm) Dia | 1 Lb (0.45 Kg) | 931-9003-0016 |

$270.00

|

||

|

Tap Drill, Arbor, .625" (15.88mm) - 1.375" (34.92mm) Dia | 0.5 Lb (0.23 Kg) | 931-9003-0015A |

$180.00

|

||

|

Tap Drill Capscrew Hex Head | 931-9003-0008 |

$32.00

|

|||

|

Set Screw 10-32 X .50 | 910-0019-00504 |

$2.20

|

| Image | Description | Shipping Wt. | Item Number | Price | Qty | Order or Compare |

|---|---|---|---|---|---|---|

|

Drill Pilot 1/4" RD, 4" Long with Coupon Retainer | 0.5 Lb (0.23 Kg) | 910-8003- |

$52.80

|

| Image | Description | Shipping Wt. | Item Number | Price | Qty | Order or Compare |

|---|---|---|---|---|---|---|

|

O-Ring Lube - Barium Grease - 4 OZ | 0.5 Lb (0.23 Kg) | 971-5100-001 |

$30.00

|

||

|

O-Ring 1.60 X .210 Viton | 914-0326-1875 |

$7.00

|

|||

|

O-Ring .859 X .139 Viton | 914-0212-1875 |

$2.00

|

|||

|

O-Ring, #206, 0.484" ID X 0.139" Viton 75 Duro | 0.5 Lb (0.23 Kg) | 914-0206-1875 |

$2.00

|

Custom Manufacturing Solutions

Custom Manufacturing Solutions Drain Flushers & Sewer Cleaning Tools

Drain Flushers & Sewer Cleaning Tools  High Pressure Mechanical Pipe Plugs

High Pressure Mechanical Pipe Plugs  Hot Tap Machines & Equipment

Hot Tap Machines & Equipment  Inflatable Annular Seals, Bladders & Duct Plugs

Inflatable Annular Seals, Bladders & Duct Plugs  Inflatable Lifting Air Bags & Pipe Handlers

Inflatable Lifting Air Bags & Pipe Handlers  Inflatable Packer Carriers

Inflatable Packer Carriers  Inflation Accessories & Pipeline Fittings

Inflation Accessories & Pipeline Fittings  Low Pressure Mechanical Pipe Plugs

Low Pressure Mechanical Pipe Plugs  Multi-Flex® Chemical Resistant Inflatable Pipe Plugs

Multi-Flex® Chemical Resistant Inflatable Pipe Plugs  PeteStop® Inflatable Line Stop Pipe Plugs

PeteStop® Inflatable Line Stop Pipe Plugs  PeteStop® Line Stop Systems, Components & Tools

PeteStop® Line Stop Systems, Components & Tools  Pipe Plugs - Inflatable

Pipe Plugs - Inflatable  Pipe Plugs - Mechanical

Pipe Plugs - Mechanical  Pipeline Test Equipment

Pipeline Test Equipment  Rubber Molded Inflatable Pipe Plugs

Rubber Molded Inflatable Pipe Plugs  Temperature and Pressure Test Plugs

Temperature and Pressure Test Plugs  Tools for Contractors

Tools for Contractors