My Cart

My Cart

Recently added item(s)

Quality Products For Professionals Since 1916 ISO9001:2015

Log in

Log in

My Cart

My Cart

Quality Products for Professionals since 1916 ISO9001:2015

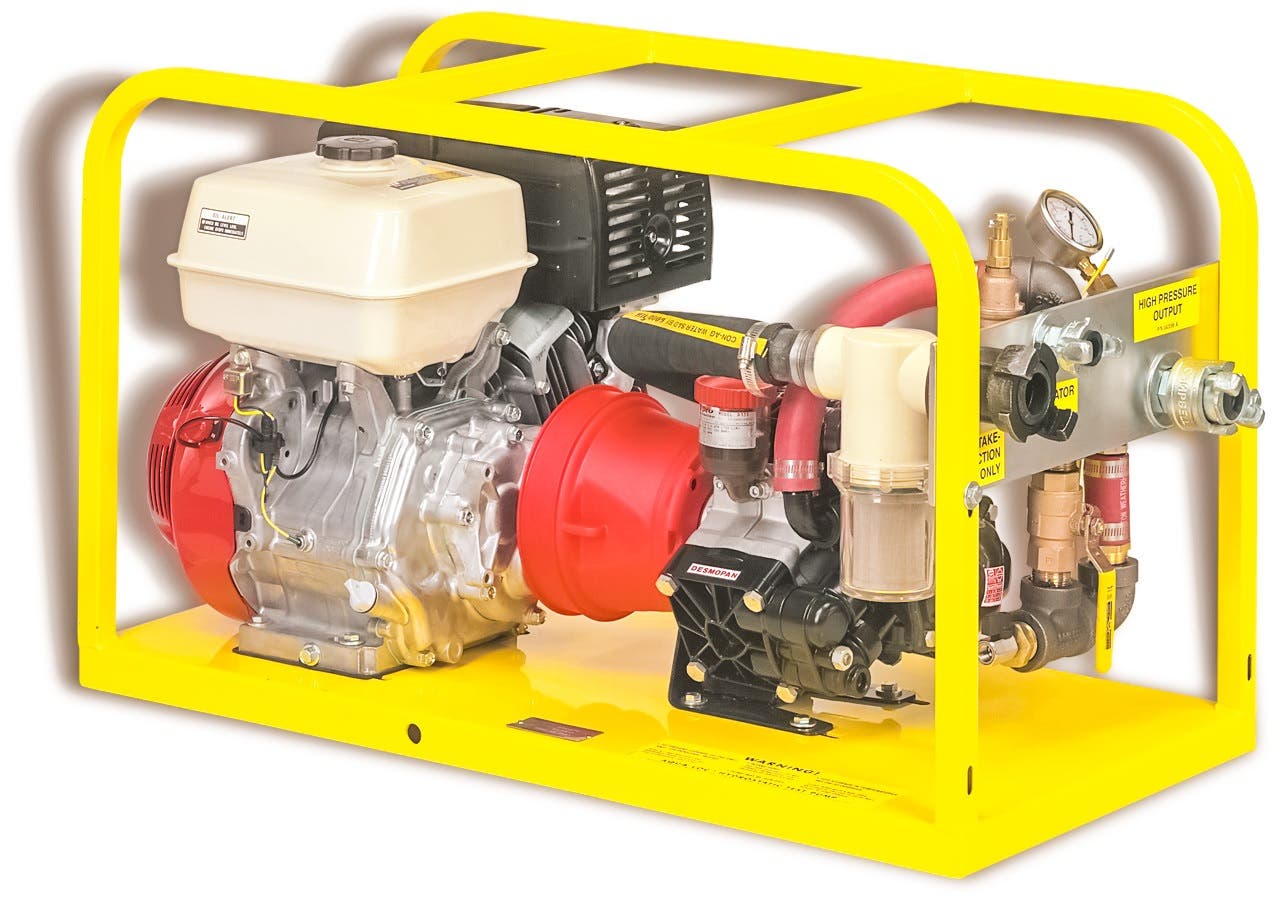

Hydrostatic Test Pump - Diaphragm Style - High-Volume 35 GPM @290 psi

Features:

Equipped with:

Hydrostatic Test Pump - Diaphragm Style - 9.5 gpm @ 550 psi

Features:

Equipped with:

Click an Item Number for More Information and to Order

| Image | Size | Pressure, PSI | Max Flow Rate | Style | Item Number | Price | Qty | Action |

|---|---|---|---|---|---|---|---|---|

|

36" L x 22" W x 22" H | 550 psi (37.92 bar) | 9.5 gpm @550 psi (37.94 bar) | Diaphragm | 938-93095- |

$4,530.00

|

||

|

36" L x 22" W x 22" H | 550 psi (37.92 bar) | 9.5 gpm @ 550 psi (37.94 bar) | Diaphragm | 938-93095-H |

$5,040.00

|

||

|

17" L X 24" W X 10.5" H | 100 psi ( 6.89 bar) Max Air | 35 gpm @ 290 psi (19.99 bar) | 938-9335-H |

$8,500.00

|

Please select and accept your Cookies Group