How to Lift and Position Heavy Equipment Without Causing Damage

Lifting and positioning large equipment requires careful planning and the appropriate equipment. Whether in construction, manufacturing, or emergency response, handling huge machinery and materials safely ensures that operations run smoothly and avoids costly delays.

Improper lifting can result in serious consequences. Equipment damage, occupational injuries, and unexpected repairs not only delay projects but also increase costs. Overloading lifting devices, using the improper tools, or neglecting to secure a weight can all result in incidents that endanger personnel.

From pneumatic lifting bags and high-pressure lift systems to cranes and hydraulic jacks, selecting the proper equipment is critical.

Understanding the Basics of Heavy Equipment Lifting

Heavy equipment refers to machinery, materials, or buildings that are too heavy to lift manually, such as industrial machines, pipelines, and construction beams. Material handling and lifting equipment are used to safely transport big loads in industries such as building, manufacturing, and emergency response.

Before lifting, certain factors must be considered. Excess weight capacity can lead to failures, while poor load balancing increases the risk of tipping or shifting. Environmental factors such as uneven ground and high winds can have an impact on safety. Using the proper instruments, such as pneumatic lifting bags, pipe handlers, or hydraulic jacks, guarantees effective and damage-free lifting. Proper planning and equipment selection help to avoid accidents and keep operations running smoothly.

Essential Equipment To Lift Heavy Objects

The use of appropriate lifting equipment ensures that heavy items are handled safely and efficiently. Different tools are specially designed to certain tasks, providing control, power, and stability.

What Equipment Is Used to Lift Heavy Objects?

- Pneumatic Lifting Bags & Pipe Handlers - Ideal for safely lifting and positioning pipes, machinery, and industrial components.

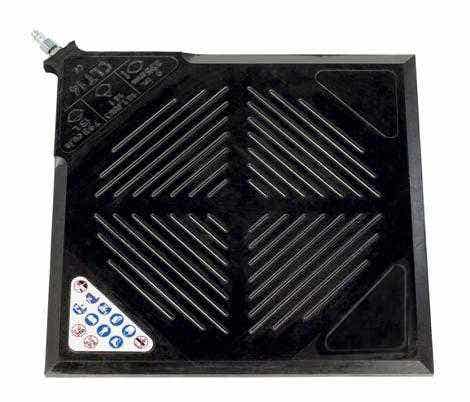

- High-Pressure Lifting Bags - Compact but powerful, ideal for tight places, emergency rescues, and HAZMAT operations.

- Cranes & Hoists – They offer stability and support for lifting large or heavy loads in construction, manufacturing, and industrial situations.

- Hydraulic Jacks – They provide precision lifting for heavy machinery, cars, and other equipment with height adjustments.

Choosing the Right Tools for Lifting Heavy Objects

Selecting the right lifting equipment depends on the weight, shape, and environment of the load. Inflatable lifting air bags are appropriate for conditions with limited space or uneven ground. They provide a controlled lift without the need for a huge setup, making them ideal for industrial applications, rescue operations, and emergency response.

For heavy-duty applications, high-pressure lifting bags provide a small yet strong solution. These bags can create tremendous lifting power even in narrow locations, making them ideal for moving large equipment, structural components, or cars.

Pipe handling equipment ensures the safe transportation and positioning of cylindrical items such as pipes and tubes. These tools, designed to hold solidly without inflicting harm, are commonly used in pipeline construction, industrial maintenance, and utility work. Cranes, hoists, and hydraulic jacks are required for large-scale lifting activities requiring greatest stability and precision.

How to Safely Lift Heavy Equipment Without Causing Damage?

Before lifting, ensure that the loads are properly balanced. Ensure that the weight is equally distributed and properly fixed to avoid shifting or tipping. Always check lifting bags, slings, and mechanical tools for signs of wear or damage before using them, as faulty equipment can cause failure and accidents.

The proper use of lifting devices provides safe operation. Position the equipment correctly, elevate gradually, and ensure stability during the process. Clear communication among workers is essential for avoiding sudden movements. To keep the lift under control, assign roles, use hand signals or radios, and keep a consistent pace.

Key Steps for Safe Lifting:

- Inspect all lifting tools before use.

- Secure the load properly to prevent shifting.

- Lift slowly and check for stability.

- Maintain clear communication among workers.

How Can You Position Heavy Equipment with Precision?

When working with heavy equipment, accurate positioning is equally crucial as lifting. Lifting bags and pipe handlers allow controlled movement, making it easier to align heavy loads, particularly in tight spaces. These devices make gradual changes, reducing the possibility of misalignment or sudden shifts.

Once the equipment is in position, it must be stabilized to prevent movement. Using supports or blocks improves balance and reduces strain on lifting equipment. Without sufficient stabilization, even minor shifts might result in structural damage or safety problems.

To avoid collision damage, lower the equipment slowly and carefully. Rushing this procedure can cause excessive strain on the load and nearby structures.

4 Common Mistakes to Avoid When Lifting Heavy Equipment

Avoiding common mistakes can help to prevent equipment damage and workplace disasters. Some of the most common errors are:

- Overloading lifting devices - Every tool has a weight limit, and exceeding it can cause equipment breakdown, resulting in serious accidents. Always check the load rating before lifting.

- Using the wrong tools - Different jobs require specific lifting equipment. Using ineffective instruments, such as lifting bags when a crane is required, can make the procedure dangerous and inefficient.

- Neglecting safety protocols – Skipping inspections, failing to properly secure loads, and poor worker communication can all lead to accidents and costly damage.

- Rushing through the process - Lifting or lowering too quickly may result in instability, impact damage, or loss of control. A slow, controlled approach promotes accuracy and safety.

Conclusion

Using the appropriate lifting equipment and following to safety rules guarantees damage-free operations. Proper training allows workers to understand load limits, equipment handling, and critical safety precautions. Investing in high-quality instruments designed to specific applications boosts efficiency, reduces risks, and increases equipment durability. Heavy lifting can be done safely and successfully by following to industry best practices.

Disclaimer: The information may be used but with no warranty or liability. This information is believed to be correct but should always be double checked with alternative sources. Strictly adhere to and follow all applicable national and local regulations and practices.

Regardless of these comments, it is always necessary to read and understand manufactures instructions and local regulations prior to using any item.