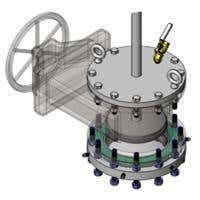

Hot Tap Machines & Equipment

Petersen Products® mechanical and pneumatic hot tappers produce hot tap holes up to 6" in diameter.

Hot tapping, also known as pressure tapping, is vital in plumbing and industrial pipeline systems. This method allows new connections to be added to an existing system without causing any disruptions. Operators performing hot tapping use various types of hot tapping equipment to safely create openings in pressurized systems, making it easier to carry out upgrades, repairs, and new branches. Petersen Products offers a wide range of hot tapping equipment, including hot tappers, pilot drills, o-rings, hole saws, hot tap sleeves, and saddles. These products are designed to ensure efficiency and safety when performing hot tapping procedures.

Our hot tapping machines are ideal for a variety of applications in industries such as water, gas, and oil. Choose between individual-sized hot tap machines or a complete hot tapping system designed to meet your operational needs.

Ready to find the right hot tapping machine for pipeline? Contact us today for expert assistance on selecting the perfect system to meet your specific hot tapping requirements.

Custom Manufacturing Solutions

Custom Manufacturing Solutions Drain Flushers & Sewer Cleaning Tools

Drain Flushers & Sewer Cleaning Tools  High Pressure Mechanical Pipe Plugs

High Pressure Mechanical Pipe Plugs  Hot Tap Machines & Equipment

Hot Tap Machines & Equipment  Inflatable Annular Seals, Bladders & Duct Plugs

Inflatable Annular Seals, Bladders & Duct Plugs  Inflatable Lifting Air Bags & Pipe Handlers

Inflatable Lifting Air Bags & Pipe Handlers  Inflatable Packer Carriers

Inflatable Packer Carriers  Inflation Accessories & Pipeline Fittings

Inflation Accessories & Pipeline Fittings  Low Pressure Mechanical Pipe Plugs

Low Pressure Mechanical Pipe Plugs  Multi-Flex® Chemical Resistant Inflatable Pipe Plugs

Multi-Flex® Chemical Resistant Inflatable Pipe Plugs  PeteStop® Inflatable Line Stop Pipe Plugs

PeteStop® Inflatable Line Stop Pipe Plugs  PeteStop® Line Stop Systems, Components & Tools

PeteStop® Line Stop Systems, Components & Tools  Pipe Plugs - Inflatable

Pipe Plugs - Inflatable  Pipe Plugs - Mechanical

Pipe Plugs - Mechanical  Pipeline Test Equipment

Pipeline Test Equipment  Rubber Molded Inflatable Pipe Plugs

Rubber Molded Inflatable Pipe Plugs  Temperature and Pressure Test Plugs

Temperature and Pressure Test Plugs  Tools for Contractors

Tools for Contractors