Pipe Plug, Inflatable High Flow Stop, 129-8 Series

Quickly Block the flow without depressurizing the pipeline!

Pipe plugs for most size, pressure, chemical, and temperature requirements

Reduce Time and Cost with Petersen® Inflatable Line Stop (ILS) systems. Call Petersen or email to discuss the benefits.

- Safety enhanced and Environmental Risk reduced with smaller hot tap hole to help maintain pipeline integrity.

- Conforms to out of round pipe configurations for better seal than mechanical stops.

- Time and Cost reduced with smaller lighter weight equipment allows and faster deployment.

- High flexibility, small deflated diameter allows installation through much smaller hot tap than much heavier costlier mechanical stops.

- Heavyweight Ballistic Nylon reinforced Polyurethane construction for long term reuse. Materials such as Kevlar and Viton available for most pressure, chemical, and temperature requirements.

- A minimal inflation pressure with water, air or other inert gas will expand the plug thus most of the pressure is applied to pipe ID for sealing.

- Small deflated plug diameter allows flexible insertion through a much smaller hot tap than mechanical Line Stops

Note: It is best to stop the flow during the installation of PeteStop® line stops. If not practical the below rule of thumb maximum flow rate seems to be acceptable.

1/2 ft/sec for the 129-0 series standard and high pressure plugs

10 ft/sec for the 129-8 series Flow Stop plugs

| Image | Dia. Max | Dia. Deflated | Dia. Hot Tap Hole, Min | Pipe Plug Inflation Max Press. | Pipeline Pressure Max Head | Port, Inflation | Port Location, Infl. | Shipping Wt. | Item Number | Price | Qty | Action |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

96" (2438mm) | 40.875" (1038mm) | 41" (1041mm) | 12 psi (0.82 bar) | 18 ft (5.48 m) | 4" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8096- |

$180,200.00

|

||

|

84" (2134mm) | 40.875" (1038mm) | 41" (1041mm) | 15 psi (1.03 bar) | 23 ft (7 m) | 4" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8084- |

$146,400.00

|

||

|

72" (1829mm) | 34.875" (886mm) | 35" (889mm) | 15 psi (1.03 bar) | 23 ft (7 m) | 4" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8072- |

$112,700.00

|

||

|

66" (1676mm) | 28.875" (733mm) | 29" (737mm) | 20 psi (1.38 bar) | 30 ft (9.14 m) | 4" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8066- |

$86,500.00

|

||

|

60" (1524mm) | 28.875" (733mm) | 29" (737mm) | 20 psi (1.38 bar) | 30 ft (9.14 m) | 4" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8060- |

$72,500.00

|

||

|

54" (1372mm) | 28.875" (733mm) | 29" (737mm) | 25 psi (1.72 bar) | 30 ft (9.14 m) | 4" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8054- |

$58,500.00

|

||

|

48" (1219mm) | 22.875" (581mm) | 23" (584mm) | 30 psi (2.07 bar) | 46 ft (14.02 m) | 4" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8048- |

$48,100.00

|

||

|

42" (1067mm) | 22.875" (581mm) | 23" (584mm) | 40 psi (2.76 bar) | 61 ft (18.59 m) | 4" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8042- |

$42,000.00

|

||

|

36" (914mm) | 18.875" (479mm) | 19" (483mm) | 60 psi (4.14 bar) | 92 ft (28.04 m) | 4" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8036- |

$39,100.00

|

||

|

32" (813mm) | 18.875" (479mm) | 19" (483mm) | 60 psi (4.14 bar) | 92 ft (28.04 m) | 2" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8032- |

$36,300.00

|

||

|

30" (762mm) | 16.875" (429mm) | 17" (432mm) | 90 psi (6.21 bar) | 138 ft (42.06 m) | 2" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8030- |

$35,200.00

|

||

|

28" (711mm) | 16.875" (429mm) | 17" (432mm) | 90 psi (6.21 bar) | 138 ft (42.06 m) | 2" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8028- |

$33,000.00

|

||

|

24" (610mm) | 14.875" (378mm) | 15" (381mm) | 100 psi (6.90 bar) | 153 ft (46.63 m) | 2" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8024- |

$17,800.00

|

||

|

19.25" (489mm) | 14.875" (378mm) | 15" (381mm) | 100 psi (6.90 bar) | 153 ft (46.63 m) | 2" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8020- |

$15,800.00

|

||

|

17.25" (438mm) | 12.875" (327mm) | 13" (330mm) | 100 psi (6.90 bar) | 153 ft (46.63 m) | 2" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8018- |

$10,800.00

|

||

|

15.25" (387mm) | 12.875" (327mm) | 13" (330mm) | 100 psi (6.90 bar) | 153 ft (46.63 m) | 2" X 300 Lb ANSI | Flow anchor | Call for Weight | 129-8016- |

$9,000.00

|

||

|

13.25" (337mm) | 11.75" (298mm) | 11.875" (302mm) | 100 psi (6.90 bar) | 153 ft (46.63 m) | 2" X 300 Lb | Flow anchor | Call for Weight | 129-8014- |

$8,600.00

|

||

|

12" (305mm) | 9.75" (248mm) | 9.875" (251mm) | 120 psi (8.28 bar) | 184 ft (56.08 m) | 2" X 300 | Flow anchor | Call for Weight | 129-8012- |

$6,500.00

|

||

|

10" (254mm) | 9.75" (248mm) | 9.875" (251mm) | 120 psi (8.28 bar) | 184 ft (56.08 m) | 2" X 300 | Flow Anchor | Call for Weight | 129-8010- |

$5,700.00

|

||

|

8" (203mm) | 7.75" (197mm) | 7.875" (200mm) | 160 psi (11.03 bar) | 246 ft (75 m) | 2" X 300 | Flow anchor | Call for Weight | 129-8008- |

$5,030.00

|

||

|

6" (152mm) | 5.75" (146mm) | 5.875" (149mm) | 160 psi (11.03 bar) | 80 psi (5.52 bar)/184.5' (56.3 m) | 1" X 150 | Flow anchor | Call for Weight | 129-8006- |

$4,670.00

|

Custom Manufacturing Solutions

Custom Manufacturing Solutions Drain Flushers & Sewer Cleaning Tools

Drain Flushers & Sewer Cleaning Tools  High Pressure Mechanical Pipe Plugs

High Pressure Mechanical Pipe Plugs  Hot Tap Machines & Equipment

Hot Tap Machines & Equipment  Inflatable Annular Seals, Bladders & Duct Plugs

Inflatable Annular Seals, Bladders & Duct Plugs  Inflatable Lifting Air Bags & Pipe Handlers

Inflatable Lifting Air Bags & Pipe Handlers  Inflatable Packer Carriers

Inflatable Packer Carriers  Inflation Accessories & Pipeline Fittings

Inflation Accessories & Pipeline Fittings  Low Pressure Mechanical Pipe Plugs

Low Pressure Mechanical Pipe Plugs  Multi-Flex® Chemical Resistant Inflatable Pipe Plugs

Multi-Flex® Chemical Resistant Inflatable Pipe Plugs  PeteStop® Inflatable Line Stop Pipe Plugs

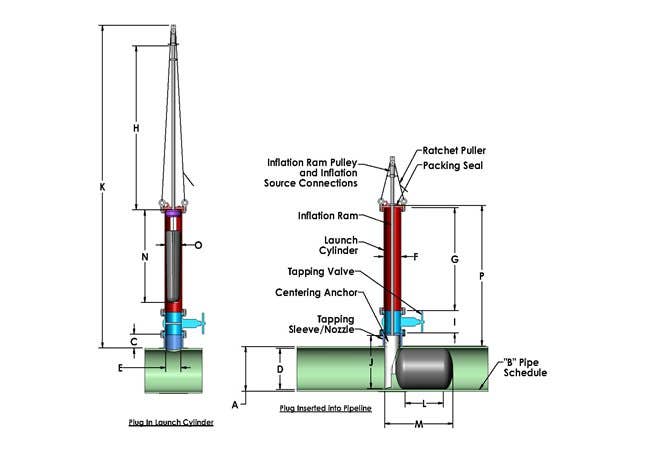

PeteStop® Inflatable Line Stop Pipe Plugs  PeteStop® Line Stop Systems, Components & Tools

PeteStop® Line Stop Systems, Components & Tools  Pipe Plugs - Inflatable

Pipe Plugs - Inflatable  Pipe Plugs - Mechanical

Pipe Plugs - Mechanical  Pipeline Test Equipment

Pipeline Test Equipment  Rubber Molded Inflatable Pipe Plugs

Rubber Molded Inflatable Pipe Plugs  Temperature and Pressure Test Plugs

Temperature and Pressure Test Plugs  Tools for Contractors

Tools for Contractors