Pipe Plug, Multi-Flex® High Expansion, 113 Series

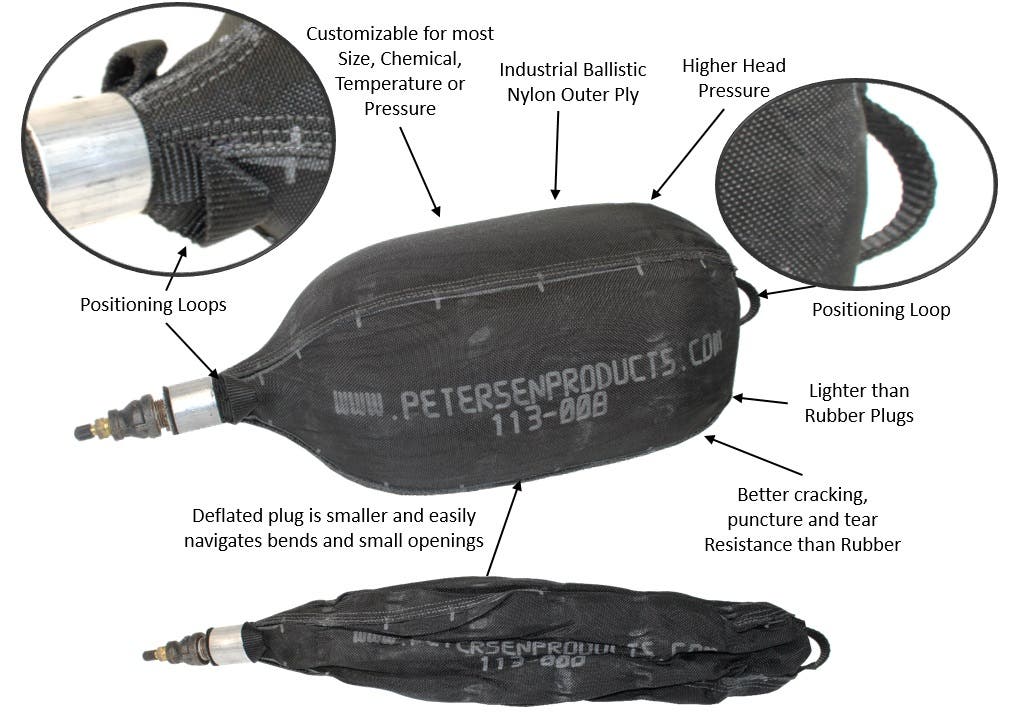

Most size, pressure, chemical, and temperature requirements

- Pipe plug for high expansion applications

- Lower pressure gas applications

- Industrial Ballistic Nylon Outer Ply

- Heavy duty plug is available in other materials for chemical and temperature requirements

- Small deflated diameter and flexibility navigates small openings

- Higher pressure and more robust than typical "Gas Plugs"

- Heavy duty plugs conform to most pipe shapes

| Image | Dia. Max | Dia. Deflated | Pipe Plug Inflation Max Press. | Pipeline Pressure Max Head | Port, Inflation | Length Deflated | Shipping Wt. | Item Number | Price | Qty | Action |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

96" (2438mm) | 10" (254mm) | 1 psi (0.06 bar) | 0.5 psi (0.03 bar)/1.2 ft (0.35 m) | 2" MNPT to 1/2" QD Plug | 228" (5791mm) | 85 Lb (38.6 Kg) | 113-096- |

$11,000.00

|

||

|

90" (2286mm) | 9" (229mm) | 1 psi (0.07 bar) | 0.5 psi (0.03 bar)/1.2 ft (0.35 m) | 2" MNPT to 1/2" QD Plug | 215" (5461mm) | 50 Lb (22.68 Kg) | 113-090- |

$9,800.00

|

||

|

84" (2134mm) | 8" (203mm) | 1 psi (0.07 bar) | 0.5 psi (0.03 bar)/1.2 ft (0.35 m) | 2" MNPT to 1/2" QD Plug | 197" (5004mm) | 51 Lb (23.13 Kg) | 113-084- |

$6,700.00

|

||

|

78" (1981mm) | 8" (203mm) | 2 psi (0.13 bar) | 1.2 ft (0.36 m) | 2" MNPT to 1/2" QC Plug | 126.58" (3215mm) | 51 Lb (23.13 Kg) | 113-078-S |

$6,564.00

|

||

|

76" (1930mm) | 2 psi (0.13 bar) | 2 ft (0.60 m) | 2" MNPT to 1/2" QD Plug | 124" (3150mm) | 36 Lbs (16.33 Kg) | 113-076-S |

$6,346.00

|

|||

|

76" (1930mm) | 7" (178mm) | 2 psi (0.13 bar) | 1 psi (0.07 bar)/2.3' (0.7m) | 2" MNPT to 1/2" QD Plug | 181" (4597mm) | 67 Lb (30 Kg) | 113-076- |

$6,346.00

|

||

|

72" (1829mm) | 7" (178mm) | 2 psi (0.13 bar) | 1 psi (0.07 bar)/2.3' (0.7 m) | 2" MNPT to 1/2" QD Plug | 170.4" (4331mm) | 70 Lb (31.75 Kg) | 113-072- |

$5,800.00

|

||

|

66" (1676mm) | 7" (178mm) | 3 psi (0.2 bar) | 1.5 psi (0.1 bar)/3.5' (1.05 m) | 2" MNPT to 1/2" QD Plug | 157.9" (4011mm) | 51 Lb (23.13 Kg) | 113-066- |

$5,200.00

|

||

|

60" (1524mm) | 7" (178mm) | 4.5 psi (0.31 bar) | 5.2 ft (1.59 m) | 2" MNPT to 1/2" QD Plug | 41 Lb (21.98 Kg) | 113-060-S |

$4,890.00

|

|||

|

60" (1524mm) | 7" (178mm) | 4.5 psi (0.31 bar) | 2.25 psi (0.16 bar)/5.2' (1.58 m) | 2" MNPT to 1/2" QD Plug | 142" (3607mm) | 41 Lb (19 Kg) | 113-060- |

$4,890.00

|

||

|

56" (1422mm) | 6" (152mm) | 5 psi (0.34 bar) | 6 ft (1.83 m) | 2" MNPT to 1/2" QD Plug | 133" (3378mm) | 26 Lb (12 Kg) | 113-056- |

$4,502.00

|

||

|

55" (1397mm) | 6" (152mm) | 5 psi (0.34 bar) | 2.5 psi (0.17 bar)/5.8' (1.76 m) | 2" MNPT to 1/2" QD Plug | 129.5" (3290mm) | 23 Lb (10.43 Kg) | 113-055- |

$4,311.00

|

||

|

54" (1372mm) | 6" (152mm) | 5 psi (0.34 bar) | 6 ft (1.83 m) | 2" MNPT to 1/2" QD Plug | 84" (2133mm) | 23 Lb (10.43 Kg) | 113-054-S |

$4,120.00

|

||

|

54" (1372mm) | 6" (152mm) | 5 psi (0.34 bar) | 2.5 psi (0.17 bar)/5.8' (1.76 m) | 2" MNPT to 1/2" QD Plug | 130" (3300mm) | 23 Lb (10.43 Kg) | 113-054- |

$4,120.00

|

||

|

50" (1270mm) | 6" (152mm) | 6.5 psi (0.44 bar) | 3.25 psi (0.22 bar)/7.5' (2.28 m) | 2" MNPT to 1/2" QD Plug | 116.8" (2967mm) | 20 Lb (9.07 Kg) | 113-050- |

$2,728.00

|

||

|

48" (1219mm) | 6" (152mm) | 6.5 psi (0.44 bar) | 3.25 psi (0.22 bar)/7.5' (2.28 m) | 2" MNPT to 1/2" QD Plug | 115" (2921mm) | 29 Lb (13.2 Kg) | 113-048- |

$2,470.00

|

||

|

46" (1168mm) | 7 psi (0.48 bar) | 7 ft (2.13 m) | 2" MNPT to 1/2" QD Plug | 111" (2819mm) | 20 Lb (9.07 Kg) | 113-046- |

$2,389.00

|

|||

|

45" (1143mm) | 6" (152mm) | 6.5 psi (0.44 bar) | 3.25 psi (0.22 bar)/7.5' (2.28 m) | 2" MNPT to 1/2" QD Plug | 111" (2819mm) | 20 Lb (9.07 Kg) | 113-045- |

$2,399.00

|

||

|

44" (1118mm) | 6" (152mm) | 7 psi (0.48 bar) | 3.5 psi (0.24 bar)/8' (2.5 m) | 2" MNPT to 1/2" QD Plug | 106.5" (2705mm) | 18 Lb (8.16 Kg) | 113-044- |

$2,270.00

|

||

|

42" (1067mm) | 6" (152mm) | 9 psi (0.62 bar) | 4.5 psi (0.31 bar)/10' (3.2 m) | 3ft Hose with Schrader Tire Valve | 102.5" (2604mm) | 17 Lb (7.71 Kg) | 113-042-H |

$3,120.00

|

||

|

42" (1067mm) | 6" (152mm) | 9 psi (0.62 bar) | 4.5 psi (0.31 bar)/10' (3.2 m) | hose 3' (914mm) and Schrader Tire Valve | 102.5" (2604mm) | 17 Lb (7.71 Kg) | 113-042- |

$2,160.00

|

||

|

36" (914mm) | 5" (127mm) | 9 psi (0.62 bar) | 4.5 psi (0.31 bar)/10' (3.2 m) | 2" MNPT to 1/2" QD Plug | 88.3" (2243mm) | 20 Lb (9.07 Kg) | 113-036- |

$1,780.00

|

||

|

34" (864mm) | 5" (127mm) | 9 psi (0.62 bar) | 4.5 psi (0.31 bar)/10' (3.2 m) | 2" MNPT to 1/2" QD Plug | 84.25" (2139mm) | 15 Lb (6.80 Kg) | 113-034- |

$1,510.00

|

||

|

33" (838mm) | 5" (127mm) | 9 psi (0.62 bar) | 4.5 psi (0.31 bar)/10' (3.2 m) | 2" MNPT to 1/2" QD Plug | 81.7" (2075mm) | 14 Lb (6.35 Kg) | 113-033- |

$1,390.00

|

||

|

32" (813mm) | 5" (127mm) | 9 psi (0.62 bar) | 4.5 psi (0.31 bar)/10' (3.2 m) | 2" MNPT to 1/2" QD Plug | 79" (2007mm) | 13 Lb (5.90 Kg) | 113-032- |

$1,390.00

|

||

|

30" (762mm) | 5" (127mm) | 9 psi (0.62 bar) | 4.5 psi (0.31 bar)/10' (3.2 m) | 2" MNPT to 1/2" QD Plug | 94" (2387mm) | 16 Lb (7.26 Kg) | 113-030- |

$1,210.00

|

||

|

26" (660mm) | 4.5" (114mm) | 10 psi (0.68 bar) | 5 psi (0.34 bar)/11' (3.5 m) | 2" MNPT to 1/2" QD Plug | 66" (1676.4mm) | 10 Lb (4.54 Kg) | 113-026- |

$910.00

|

||

|

25" (61035mm) | 4" (102mm) | 10 psi (0.68 bar) | 5 psi (0.34 bar)/11' (3.5 m) | 2" MNPT to 1/2" QD Plug | 73" (1854mm) | 10 Lb (4.54 Kg) | 113-025- |

$884.00

|

||

|

24" (610mm) | 4" (102mm) | 10 psi (0.68 bar) | 5 psi (0.34 bar)/11' (3.5 m) | 2" MNPT to 1/2" QD Plug | 10 Lb (4.54 Kg) | 113-024-S |

$800.00

|

|||

|

24" (610mm) | 4" (102mm) | 10 psi (0.68 bar) | 5 psi (0.34 bar)/11' (3.5 m) | 2ft Hose with Tire Valve | 61" (1549mm) | 10 Lb (4.54 Kg) | 113-024-H |

$920.00

|

||

|

24" (610mm) | 4" (102mm) | 10 psi (0.68 bar) | 5 psi (0.34 bar)/11' (3.5 m) | 2" MNPT to 1/2" QD Plug | 61" (1549mm) | 10 Lb (4.54 Kg) | 113-024- |

$800.00

|

||

|

20" (508mm) | 4" (102mm) | 20 psi (1.37 bar) | 10 psi (0.69 bar)/23' (7.03 m) | 2" MNPT to 1/2" QD Plug | 56" (1422mm) | 7 Lb (3.18 Kg) | 113-020- |

$680.00

|

||

|

18" (457mm) | 3.5" (89mm) | 22 psi (1.51 bar) | 11 psi (0.76 bar)/25' (7.7 m) | 2" MNPT to 1/2" QD Plug | 47.75" (1213mm) | 10 Lb (4.54 Kg) | 113-018- |

$600.00

|

||

|

16" (406mm) | 3" (76mm) | 25 psi (1.72 bar) | 29 ft (8.84 m) | 1" MNPT to 1/4" QD Plug | 26.5" (673mm) | 6 Lb (2.72 Kg) | 113-016-S |

$480.00

|

||

|

16" (406mm) | 3" (76mm) | 25 psi (1.72 bar) | 12.5 psi (0.86 bar)/29' (8.8m) | 1" MNPT to 1/4" QD Plug | 42.50" (1080mm) | 6 Lb (2.72 Kg) | 113-016- |

$480.00

|

||

|

15" (381mm) | 2.5" (64mm) | 25 psi (1.72 bar) | 12.5 psi (0.86 bar)/29' (8.8m) | 1" MNPT to 1/4" QD Plug | 39" (991mm) | 5 Lb (2.27 Kg) | 113-015- |

$484.00

|

||

|

14" (356mm) | 2.5" (64mm) | 25 psi (1.72 bar) | 29 ft (8.84 m) | 1" MNPT to 1/4" QD Plug | 35" (889mm) | 5 Lb (2.27 Kg) | 113-014-EP |

$1,025.00

|

||

|

14" (356mm) | 2.5" (64mm) | 25 psi (1.72 bar) | 12.5 psi (0.86 bar)/29' (8.8m) | 1" MNPT to 1/4" QD Plug | 38.8" (986mm) | 5 Lb (2.27 Kg) | 113-014- |

$410.00

|

||

|

12" (305mm) | 2.5" (64mm) | 25 psi (1.72 bar) | 12.5 psi (0.86 bar)/29' (8.8 m) | Schrader Tire Valve | 23" (584mm) | 3 Lb (1.36 Kg) | 113-012-S |

$310.00

|

||

|

12" (305mm) | 2.5" (64mm) | 25 psi (1.72 bar) | 12.5 psi (0.86 bar)/29' (8.8m) | 2ft Hose with Tire Valve | 30" (762mm) | 3 Lb (1.36 Kg) | 113-012-H |

$350.00

|

||

|

12" (305mm) | 2.5" (64mm) | 25 psi (1.72 bar) | 12.5 psi (0.86 bar)/29' (8.8m) | Schrader Tire Valve | 32.3" (820.4mm) | 3 Lb (1.36 Kg) | 113-012- |

$310.00

|

||

|

11.06" (281mm) | 25 psi (1.72 bar) | 29 ft (8.84 m) | Tire Valve | 17" (432mm) | 3 Lb (1.36 Kg) | 113-011- |

$313.00

|

|||

|

10" (254mm) | 2" (51mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.6 m) | 2ft Hose with Schrader Tire Valve | 31" (787mm) | 3 Lb (1.36 Kg) | 113-010-H |

$310.00

|

||

|

10" (254mm) | 2" (51mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.6 m) | Schrader Tire Valve | 28.50" (724mm) | 3 Lb (1.36 Kg) | 113-010- |

$270.00

|

||

|

8" (203mm) | 2" (51mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.67 m) | Schrader Tire Valve | 14.5" (368mm) | 3 Lb (1.36 Kg) | 113-008-S |

$441.00

|

||

|

8" (203mm) | 2" (51mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.6 m) | 2ft Hose with Schrader Tire Valve | 21" (534mm) | 3 Lb (1.36 Kg) | 113-008-H |

$260.00

|

||

|

8" (203mm) | 2" (51mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.6 m) | Schrader Tire Valve | 23.25" (591mm) | 3 Lb (1.36 Kg) | 113-008- |

$220.00

|

||

|

6" (152mm) | 1.65" (42mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.67 m) | Schrader Tire Valve | 10.3" (262mm) | 2 Lb (0.91 Kg) | 113-006-S |

$180.00

|

||

|

6" (152mm) | 1.65" (42mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.6 m) | 2ft Hose with Schrader Tire Valve | 17" (432mm) | 2 Lb (0.91 Kg) | 113-006-H |

$220.00

|

||

|

6" (152mm) | 1.65" (42mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.6 m) | Schrader Tire Valve | 19.25" (489mm) | 2 Lb (0.9 Kg) | 113-006- |

$180.00

|

||

|

5" (127mm) | 1.5" (38mm) | 30 psi (2.06 bar) | 15 psi (1.03 bar)/35' (10.6 m) | Schrader Tire Valve | 16.73" (425mm) | 2 Lbs (0.91 Kg) | 113-005- |

$160.00

|

||

|

4" (102mm) | 1.25" (32mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.6 m) | 2ft Hose with Schrader Tire Valve | 10" (254mm) | 2 Lb (0.91 Kg) | 113-004-H |

$190.00

|

||

|

4" (102mm) | 1.25" (32mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.6 m) | 1ft Hose with Schrader Tire Valve | 10" (254mm) | 2 Lb (0.91 Kg) | 113-004- |

$150.00

|

||

|

3" (76mm) | 1" (25mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.6 m) | 1ft Hose with Schrader Tire Valve | 9" (229mm) | 2 Lb (0.91 Kg) | 113-003- |

$120.00

|

||

|

2" (51mm) | 1" (25mm) | 30 psi (2.07 bar) | 15 psi (1.03 bar)/35' (10.67 m) | 1ft Hose with Schrader Tire Valve | 7" (178mm) | 2 Lb (0.91 Kg) | 113-002- |

$120.00

|

Key Features and Benefits of 113-Series High Expansion Pipe Plugs

Petersen Products offers high-quality Multi-Flex® pipe plugs, designed to meet diverse industrial needs. Below are the key features and benefits of these pipe plugs:

- Suited for High Expansion Applications: The Multi-Flex® high expansion pipe plugs are specifically designed for high expansion scenarios. They can expand significantly, making them suitable for various pipe sizes and shapes. This adaptability ensures that they can be used in various industrial applications, providing a workable seal even in challenging environments.

- Low Pressure Gas Applications: These pipe plugs are perfect for low-pressure gas systems. They provide effective sealing and restraining capabilities, ensuring safety and efficiency in gas handling operations. Their design helps maintain integrity and performance in lower-pressure environments.

- Durable Construction: The outer ply of the pipe plugs is made with industrial ballistic nylon, providing exceptional durability and resistance to wear and tear. This robust material ensures the plugs can withstand harsh conditions and prolonged use without compromising performance.

- Available in Various Materials: These heavy-duty plugs can be customized with different materials (ballistic nylon and Kevlar) and coatings like viton, nitrile, polyurethane, EPDM and others to meet your specific chemical and temperature requirements. This allows you to meet precise operational needs, ensuring optimal performance under varying conditions.

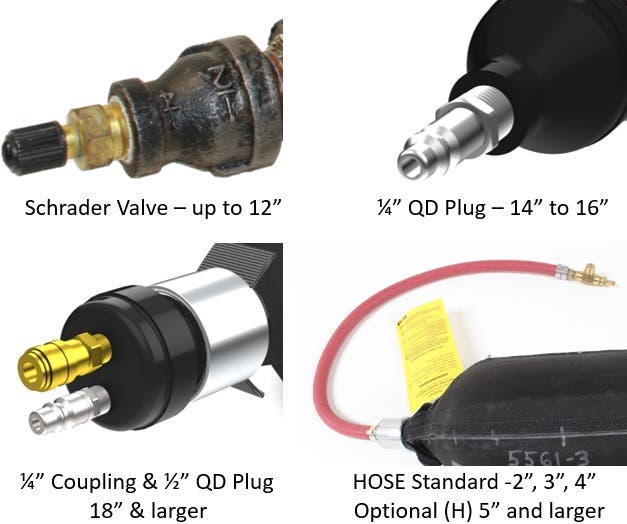

- Variety of Configurations: The 113-Series has an oblong design to provide a large contact area with the pipeline. It can be made shorter where it almost looks like an inflated ball for applications with space requirements. Also, the pipe plug can be configured with a hose versus just having a plug end.

- Small Deflated Diameter and Flexibility: The pipe plugs feature a small deflated diameter and high flexibility, allowing them to navigate through small openings easily. This design makes them ideal for applications where access is limited, ensuring that they can be installed and removed with minimal hassle. The pipe plugs also are able to snake through bends and turns with ease.

- Conform to Most Pipe Shapes: These heavy-duty plugs are designed to conform to most pipe shapes, providing a secure and reliable seal. This versatility makes them suitable for various piping systems, ensuring compatibility and effectiveness.

- Small Storage Requirements: These pipe plugs require small storage space when deflated. This compactness benefits transportation and storage, making them a convenient choice for various industrial operations.

- Environmental Compliance: These pipe plugs are manufactured in compliance with environmental standards, ensuring minimal environmental impact. This commitment to sustainability is an added benefit for environmentally conscious industries.

- Lightweight Design: Despite their robust construction, the pipe plugs are lightweight, making them easy to transport and handle. This feature is particularly beneficial in applications where portability is essential.

Applications of 113 Series Multi-Flex® High Expansion Pipe Plugs

Pipe plugs are essential for various industrial applications. Below are some of the applications where these equipment are commonly used:

- Water and Wastewater Management: These pipe plugs are widely used in water and wastewater management systems to block pipes during repair or maintenance work. Their ability to navigate small openings and conform to pipe shapes makes them highly effective in preventing contamination and managing water flow.

- Chemical Processing Plants: These plugs are used to isolate piping sections for maintenance or cleaning without shutting down the entire system. Their resistance to various chemicals make them suitable for such harsh environments, ensuring safety and reliability.

- Pipeline Testing and Maintenance: Multi-Flex® Pipe Plugs are used during pipeline testing and maintenance. They can be used to seal off sections of the pipeline, allowing for pressure tests, leak detection, and integrity assessments. Their ability to conform to different pipe shapes ensures a secure seal, facilitating accurate testing results.

- Municipal and Utility Services: Municipal and utility services use these plugs for routine water, sewer, and gas lines maintenance. Their versatility and ease of use make them a practical choice for various applications, ensuring uninterrupted service and efficient repairs.

- Oil and Gas Industry: The oil and gas industry uses these high-expansion pipe plugs for temporary sealing during construction, maintenance, and repairs. Their robustness and ability to handle higher pressures make them ideal for upstream and downstream applications, including pipelines, refineries, and storage facilities.

How to Install the 113 Series High Expansion Pipe Plugs?

Installing high-expansion pipe plugs correctly ensures effective sealing and reliable performance. Follow these steps to ensure proper installation, from preparing equipment and positioning the plug to inflating and securing it.

- BE SAFE: Ensure all personnel involved are trained and aware of potential hazards. NEVER use an inflatable plug when its failure could cause injury or catastrophic damage or as the only means of protection for personnel working downstream. Keep all personnel out of the plug end area – DANGER ZONE – when plug is in use.

- Prepare Equipment: Gather all necessary equipment such as 113-series pipe plug, inflation hose, low-pressure alarm, adapter, inflation controller, pressure gauge, and relief valve. Ensure all components are connected properly.

- Inspect the Pipeline being Plugged: Debris or protrusions in the pipeline can damage a seal or rupture inflatable plugs. Thoroughly clean the pipeline before insertion of the Pipe plug. Maximum rated pressures assume Pipe plugs are fully inserted into clean dry pipes.

- Position the Plug: Use a rope or cable on the positioning loops to guide the plug into the pipe. Insert the plug into the pipe carefully to ensure correct placement.

- Block or Anchor the Plug: All pipe plugs must be blocked or anchored adequately against a force equal to the head pressure times the cross-sectional area of the pipe.

- Connect Air Source: Attach the inflation hose to an appropriate air source.

- Set Inflation Pressure: Open the pressure regulator and set it to the plug's maximum inflation pressure.

- Inflate the Plug: Turn the inflation controller knob to start inflating the plug. Once the desired pressure is reached, turn the knob to hold the pressure. Do not exceed the pressures on the plug label.

- Activate Alarm: Turn on the low-pressure alarm to monitor for any pressure changes.

- Finalize Inflation: Turn the inflation controller knob to inflate the plug again if necessary, and then turn the knob to hold.

- Close Regulator: Once the plug is securely inflated, close the pressure regulator.

- Deactivate Alarm: Turn off the low-pressure alarm.

- Deflate the Plug: Turn the inflation controller to deflate the plug as needed.

Maintenance and Care Tips

Proper maintenance and care of pipe plugs is essential to ensure their longevity and performance. Here are some essential tips to help you maintain and care for your pipe plugs effectively:

- Regular Inspection: Periodically check for wear, tear, and damage to identify any issues early and prevent failures during use.

- Cleaning: Clean the plugs thoroughly after each use to remove debris and chemicals that could cause deterioration.

- Storage: Store in a cool, dry place away from direct sunlight and chemicals to prevent material degradation and maintain elasticity.

- Lubrication: Apply appropriate lubricants to moving parts regularly to ensure smooth operation and prevent seizing.

- Pressure Testing: Regularly test the plugs to ensure they can withstand the required pressure, maintaining safety and effectiveness.

Are you looking for effective pipe plugs for your industrial needs? Our Multi-Flex® Pipe Plugs offer superior durability, customization, and versatility for various applications. Ensure reliable performance and safety in your projects. Visit Petersen Products website now for more details and to find the perfect solution for your needs.

FAQs on Pipe Plugs

How does the compact deflated diameter benefit the use of pipe plugs?

The compact deflated diameter allows the plugs to navigate through small openings and tight spaces, facilitating easy installation and removal in various applications.

How does an industrial ballistic nylon outer layer benefit pipe plugs?

Industrial ballistic nylon provides high durability and resistance to wear and tear, extending the plug’s lifespan in harsh conditions. It also doesn’t have age degradation like rubber.

Custom Manufacturing Solutions

Custom Manufacturing Solutions Drain Flushers & Sewer Cleaning Tools

Drain Flushers & Sewer Cleaning Tools  High Pressure Mechanical Pipe Plugs

High Pressure Mechanical Pipe Plugs  Hot Tap Machines & Equipment

Hot Tap Machines & Equipment  Inflatable Annular Seals, Bladders & Duct Plugs

Inflatable Annular Seals, Bladders & Duct Plugs  Inflatable Lifting Air Bags & Pipe Handlers

Inflatable Lifting Air Bags & Pipe Handlers  Inflatable Packer Carriers

Inflatable Packer Carriers  Inflation Accessories & Pipeline Fittings

Inflation Accessories & Pipeline Fittings  Low Pressure Mechanical Pipe Plugs

Low Pressure Mechanical Pipe Plugs  Multi-Flex® Chemical Resistant Inflatable Pipe Plugs

Multi-Flex® Chemical Resistant Inflatable Pipe Plugs  PeteStop® Inflatable Line Stop Pipe Plugs

PeteStop® Inflatable Line Stop Pipe Plugs  PeteStop® Line Stop Systems, Components & Tools

PeteStop® Line Stop Systems, Components & Tools  Pipe Plugs - Inflatable

Pipe Plugs - Inflatable  Pipe Plugs - Mechanical

Pipe Plugs - Mechanical  Pipeline Test Equipment

Pipeline Test Equipment  Rubber Molded Inflatable Pipe Plugs

Rubber Molded Inflatable Pipe Plugs  Temperature and Pressure Test Plugs

Temperature and Pressure Test Plugs  Tools for Contractors

Tools for Contractors